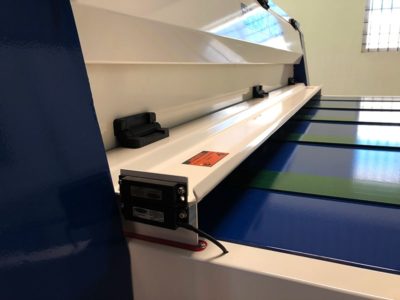

A lot of our competitors coat their flatbed roller press die-cutter machines with polyurethane which is complicated and difficult to renew after wear. These press rollers then need to be re-coated by their manufacturers which can weigh up to 1000 kilograms thereby, not only does it consume time, but it is also very expensive.

U-Pack has developed a more efficient and economical designs whereby customers keep our unique brand of polypropylene Cutting Anvil Sleeves in stock and perform sleeve changes on site with their own maintenance staff without the need for expertise from outside to install them, thereby minimizing cost.